Model No.: WH

Brand: Weihua

Certification: Other

Condition: New

Maximum Lifting Weight: >200t

Maximum Lifting Height: 10-15m

Operation Form: Cabin

Type: Other

Main Girder Form: Double Girder

Packaging: Woden Case, Rain Cloth, etc.

Productivity: 300 sets

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 80 sets per month

Certificate: ISO 9001 ISO 14001 OHSAS 18001 GB/T 19001-2008/ISO 9001: 2008

HS Code: 8426193000

Port: Qingdao,Tianjin,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

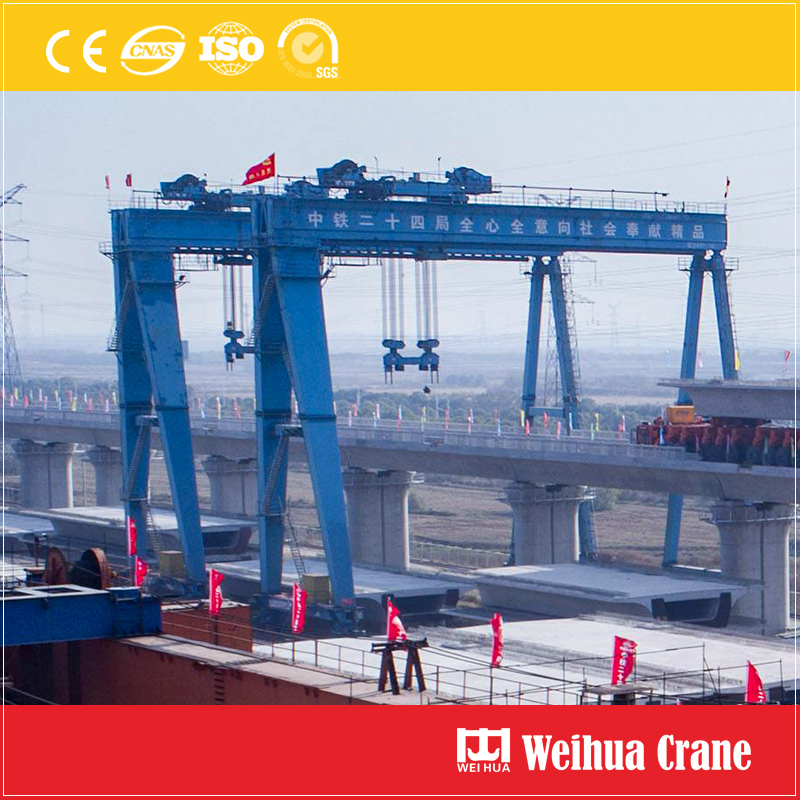

Gantry Crane for railway construction is a project crane employed to handle rail track, sleeper, concrete section, bridge beams, etc. for railway construction. The railway construction gantry crane can be designed with different lift height, span and capacity.

This railway construction gantry crane is composed of main girder, rigid and flexible supporting legs, travelling mechanism, hoisting mechanism, electric control system, hydraulic system, driver cabin, railing, ladder and walking plat. Weihua also provide professional railway construction project cranes such as beam handling crane, beam erection crane, track collection crane, and other equipment.

As a leading crane manufacturer in China, Weihua Group has provided a large number of highly reliable project cranes for the major railway projects in China. For example, the large-span project gantry crane for Lhasa-Shigatse Railway project has more stringent reliability requirements. The operating altitude is more than 3700 Meters and the geothermal temperature is 40 ~ 90 ℃. In the face of difficulties, Weihua project crane team seriously study the technical solutions, and carry out manufacturing in strict accordance with the project quality and progress, and delivery of products on schedule with the indicators in full compliance with customer requirements.

Features of Gantry Crane for Railway Construction:

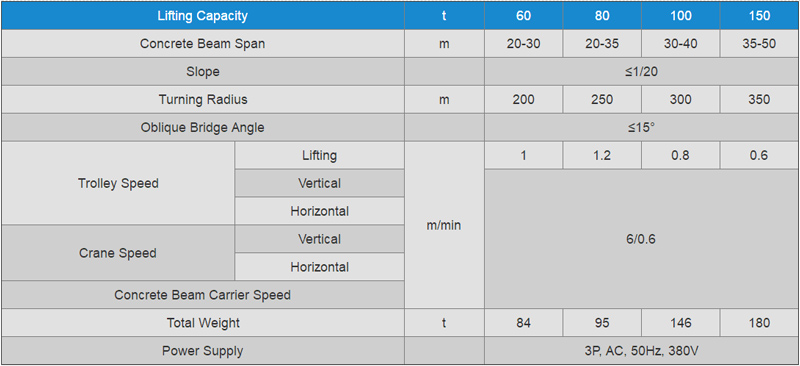

1. Both rubber tire type and rail-mounted type gantry crane are available;

2. Hydraulic driven of walking, steering and lifting;

3. Crane carries out straight, oblique and rampage traveling;

4. Good adaptability, high working efficiency, small space occupied;

5. Special spreader for hoisting and shifting large concrete beam/bridge;

6. It realizes synchronous work of 2 cranes and 2 trolleys with max lifting height 30m;

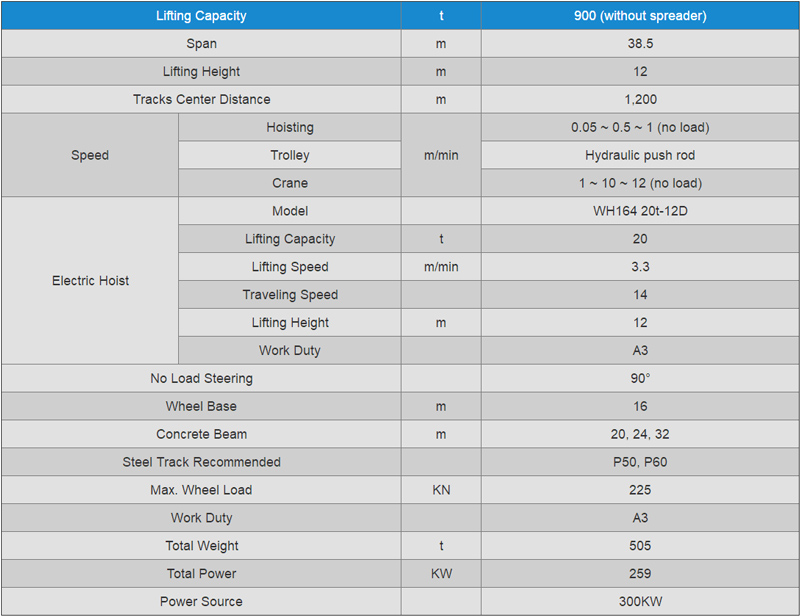

7. The max wheel load is 22t when hoisting 900t weight;

8. 90° shift for rail type gantry crane to achieve horizontal or vertical walking;

9. 4 points for lifting and 3 points for balance to ensure even stress of the wire rope;

10. Precise positioning for lowering down;

11. Hydraulic push for trolley to realize various lifting and save the cost;

12. For the 4 hoists, it can be single use or combine use of 2 or 4 hoists while the hardware and software are interlocked for operation safety.

For Beam Lifting:

For Beam Shifting:

For Beam Erecting:

Product Categories : Gantry Crane > Project Crane