Model No.: WH

Brand: Weihua

Certification: Other

Condition: New

Maximum Lifting Weight: 20-50t

Maximum Lifting Height: 15-20m

Operation Form: Cabin

Type: Container Gantry Crane

Main Girder Form: Double Girder

Packaging: Woden Case, Rain Cloth, etc.

Productivity: 30 sets

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 80 sets per month

Certificate: ISO 9001 ISO 14001 OHSAS 18001 GB/T 19001-2008/ISO 9001: 2008

HS Code: 8426193000

Port: Qingdao,Tianjin,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

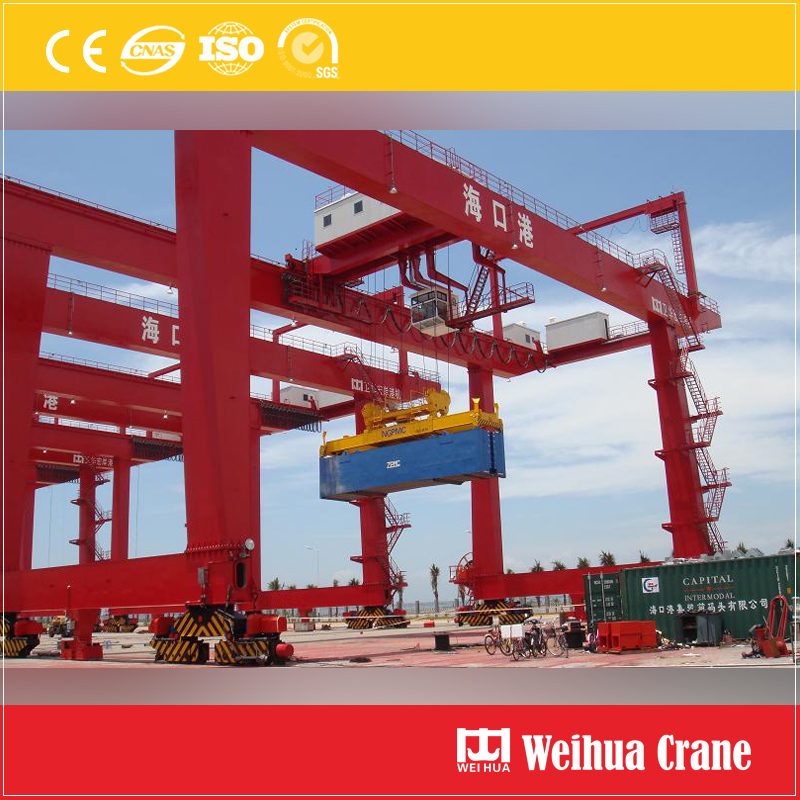

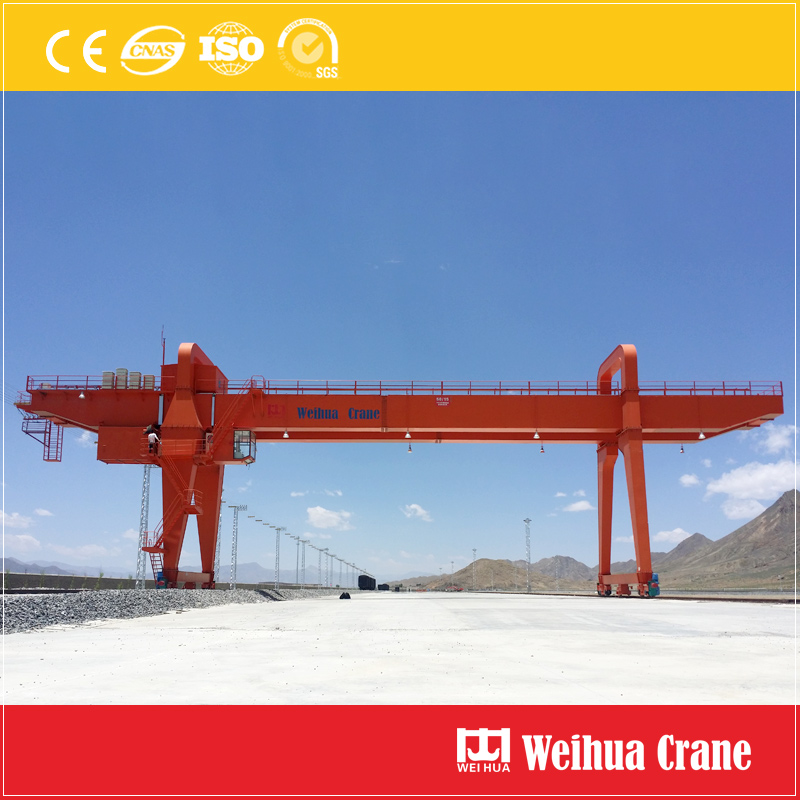

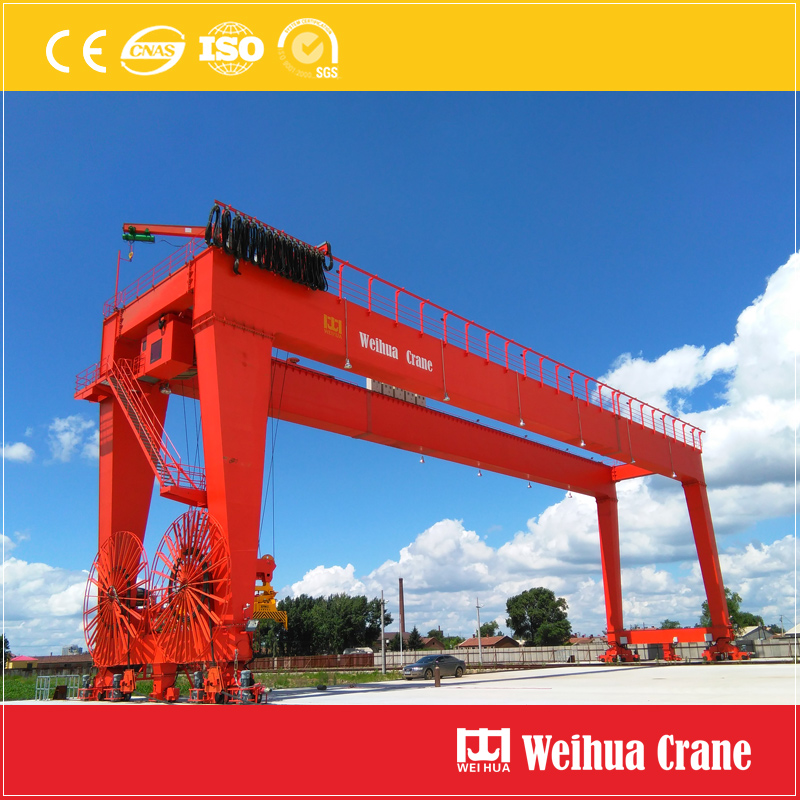

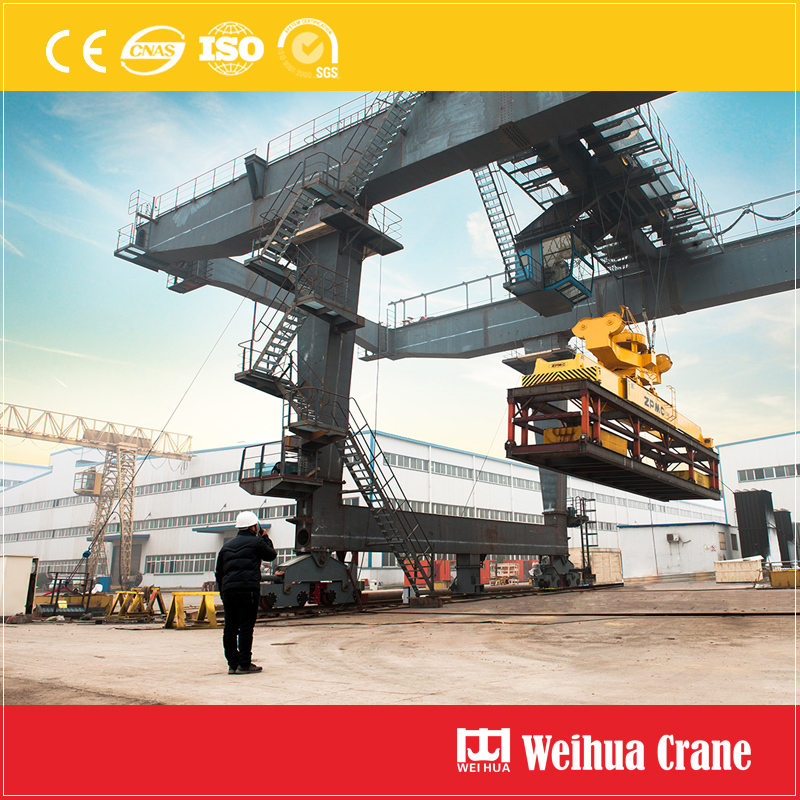

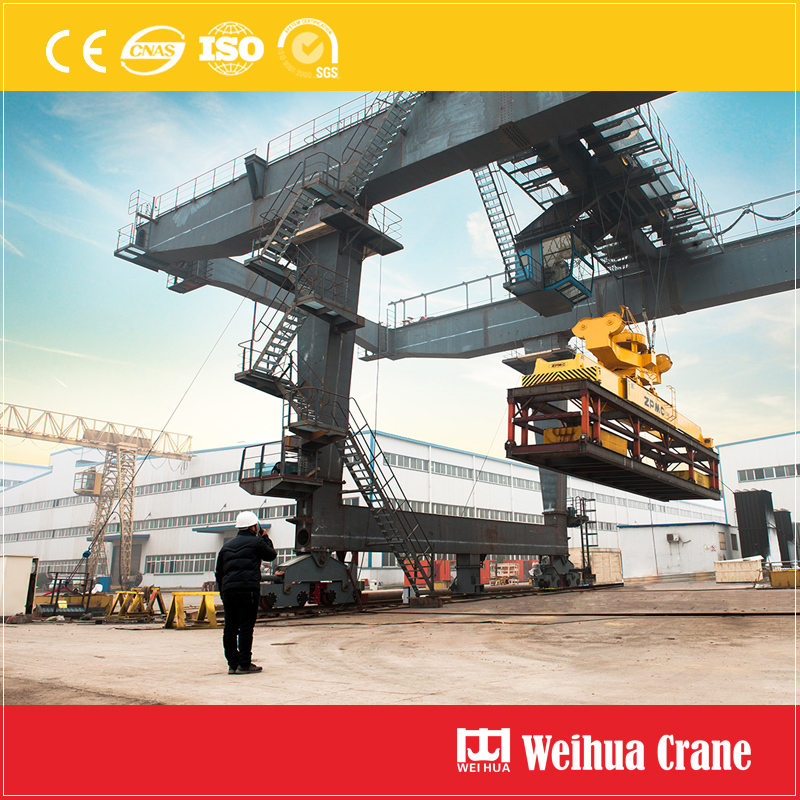

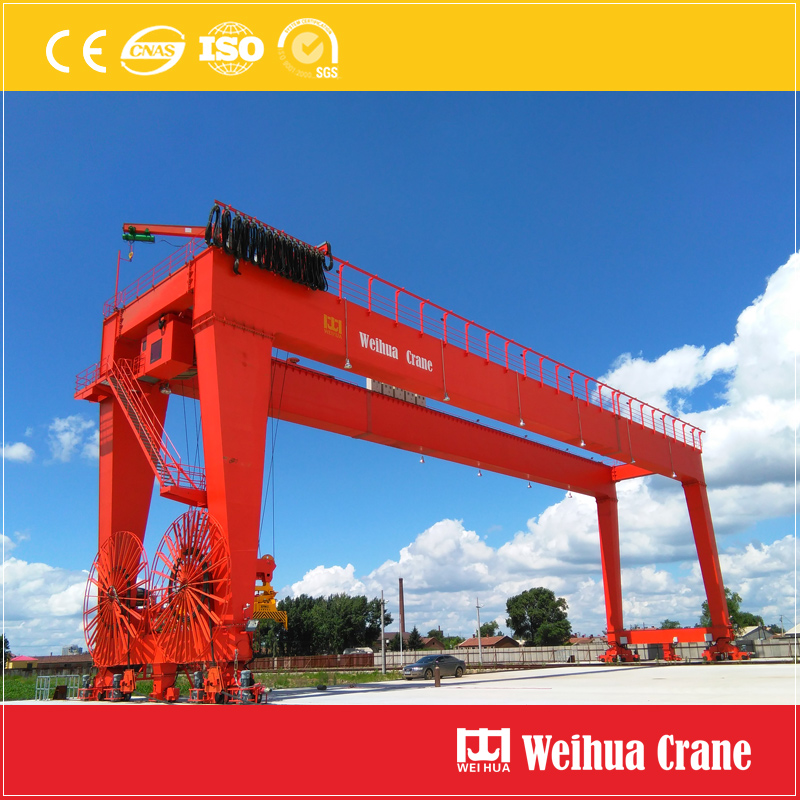

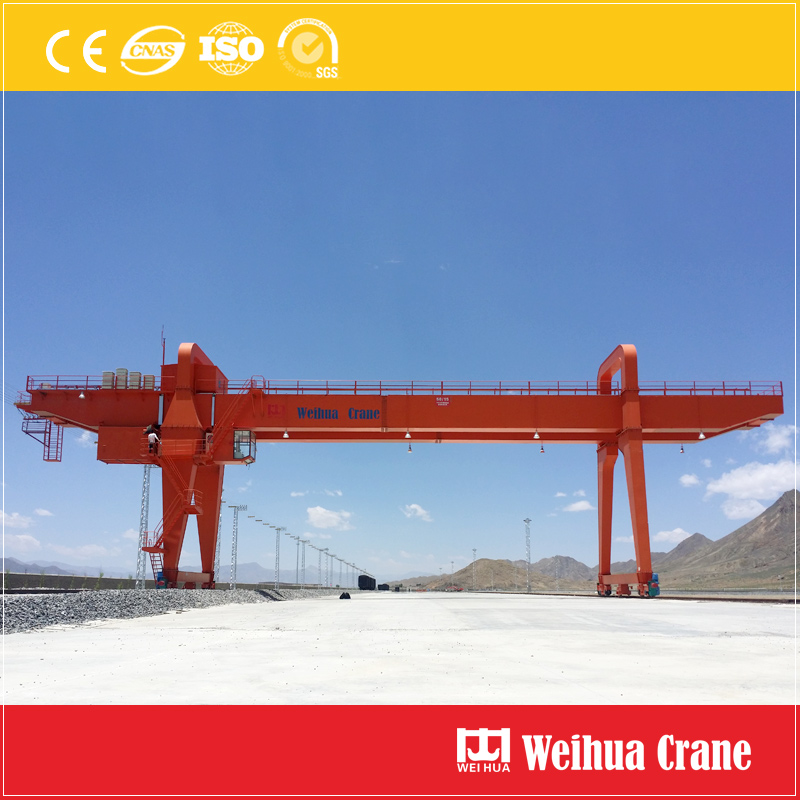

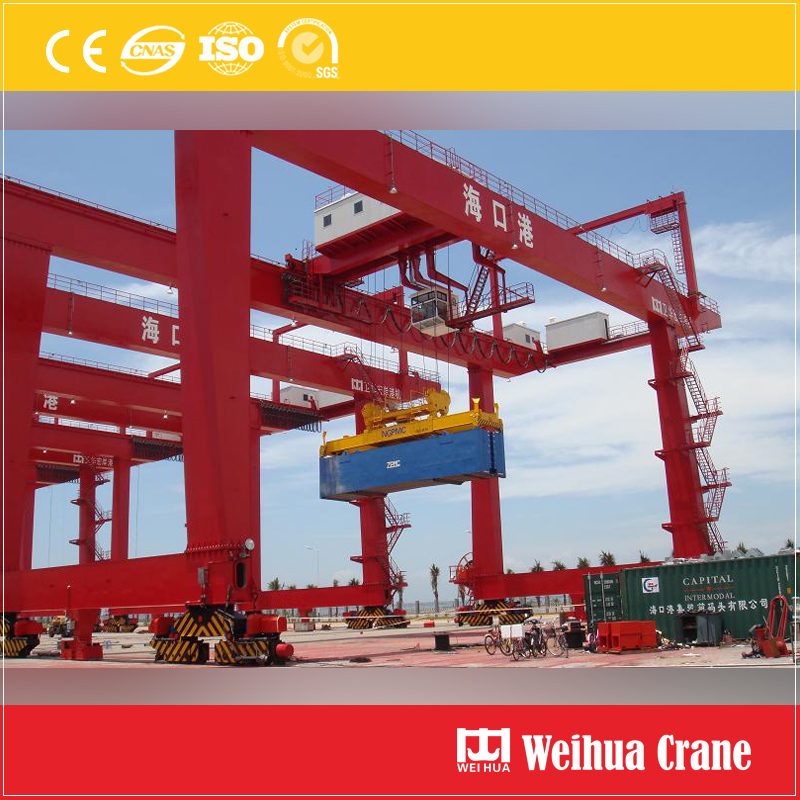

RMG crane (Rail Mounted Container Gantry Crane) is commonly employed to handle containers at sea port, railway container transship site and large container storage yards. It is composed of main girder, rigid and flexible outriggers, trolley hoisting/traveling mechanism, spreader, crane travel mechanism, electric system and cabin.

This RMG crane can be 3 kinds according to its cantilever: single cantilever, double cantilever crane, and non-cantilever. Users can choose different types depending on the different demands of yards, storage and transport ways of containers and vehicles (trucks or railway vehicles).

Features of Weihua RMG Crane:

1. Low lifting speed for low lifting height. High crane traveling speed for long-track container handling. The spreader can go over the fifth container layer as the stack of 4 layers and its lifting height depends on the requirements of storage yards

2. The trolley traveling speed depends on the span and the outreaching distance of both sides of the girder. In the case of the span and outreaching distance is short, smaller trolley traveling speed and the productivity is advisable; otherwise, the trolley traveling speed could be accordingly increased to meet productivity requirement.

3. When the span is over 40 meters, the RMG crane mechanism travels in a high speed, and both sides of outriggers would deviate because of the drag on each side is different. So there is a stabilizer equipped on this RMG crane and electric system that keep both sides of traveling mechanisms synchronous.

4. Electrical drive-control system adopts thyristor speed regulating drive AC or DC control system to meet the higher need and accomplish a better performance of speed regulating and control. Or it adopts conventional AC eddy current speed regulating control system and AC stator voltage and speed regulating drive control system.

An electric braking that equipped with thyristor speed regulating drive AC or DC control system or AC stator voltage and speed regulating drive control system is usually used as the electric control system of a high speed crane traveling mechanism. Conventional AC eddy current speed regulating drive control system which depends on the brakes to shut down traveling mechanisms should be avoided in order to prevent the huge impact to whole crane.

5. The trolley and spreader can be designed to be rotatable according to user`s requirement. The trolley can rotate 270° and spreader can rotate 360°.

Product Categories : Gantry Crane > Container Crane